Luxury will be key for ESKA in the years to come

Rienk Jan van der Kooi, CEO of Eska, explains why his 140 year-old company is a good fit for luxury brands on the lookout for sustainable solutions.

Many thanks to Alissa Demorest from Formes de Luxe Magazine for this great interview.

We started experimenting with recycling paper in the 1930s.

Eska has long been involved in recycled materials.

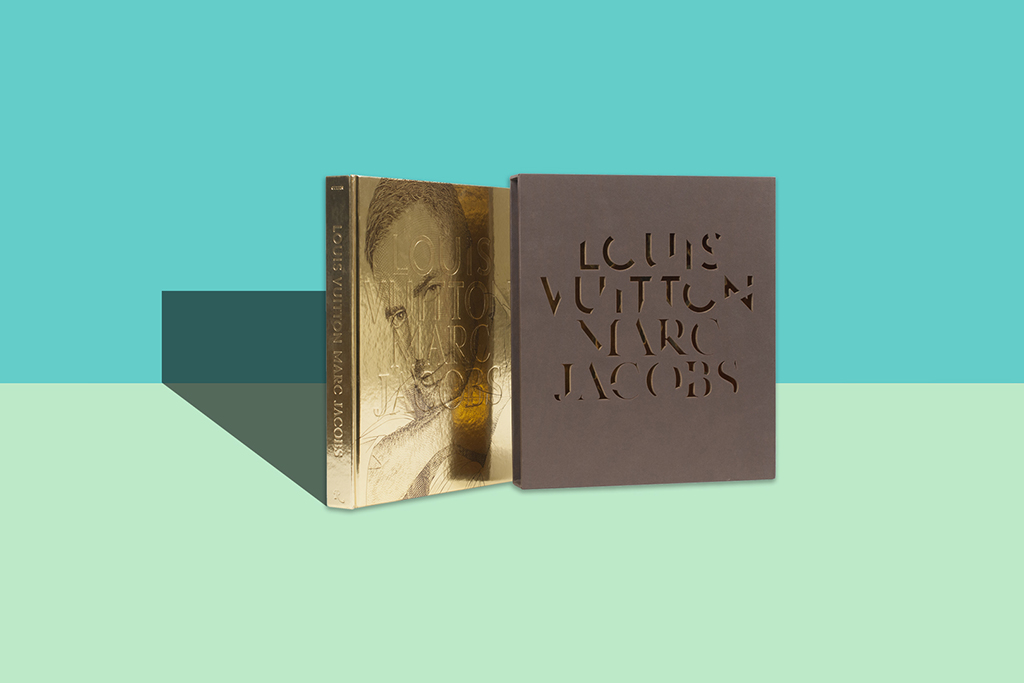

Indeed. One hundred and forty years ago we began producing board using straw and in the 1930s we started experimenting with recycling paper. At the company’s founding it produced train tickets, then expanded into the hardcover book segment followed by puzzles and board games. When we realized that our product, given its material characteristics, was used to make luxury boxes we decided to diversify to the luxury segment. Yet this was a natural move as Eska has a history of diversification: luxury is our newest segment and we see growth opportunities in developing new products and concepts. Our offer is a good fit for the luxury segment given that it matches the market’s increasing awareness regarding sustainability.

How has your luxury offer evolved?

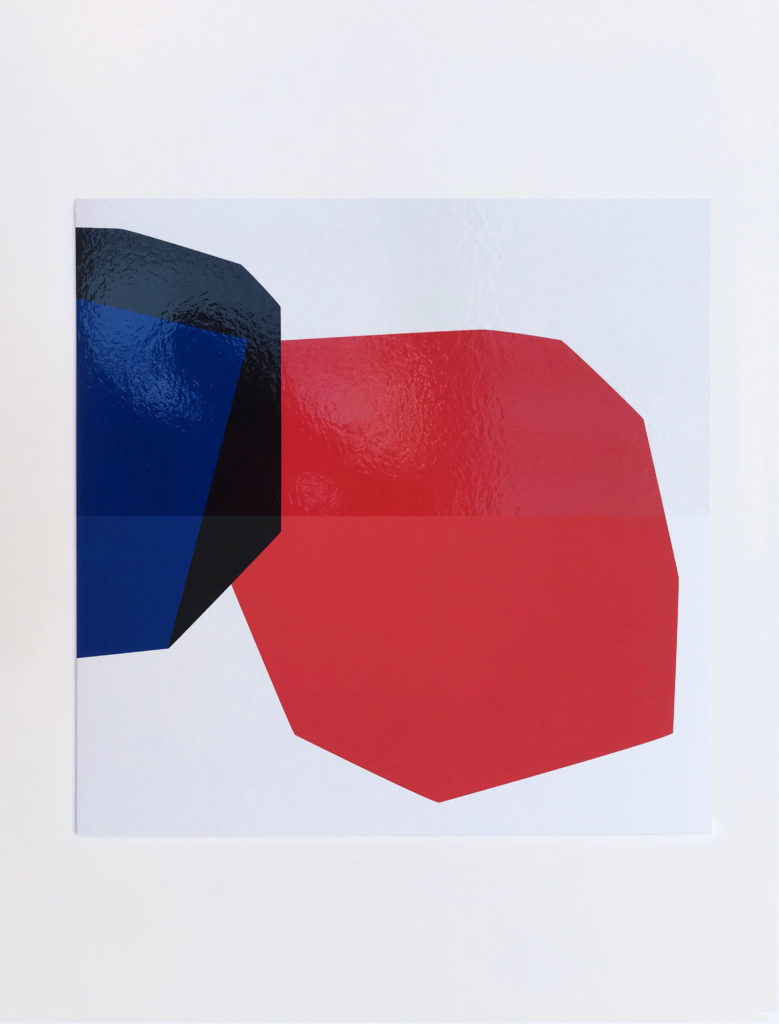

We moved into colored board with Eska Color, which we launched at Luxe Pack Monaco in 2018. Mass colored board and recycled board already exists on the market, but a product that combines the two is new. Since then we’ve continued to innovate with the launch of Eska Jeans, a product that combines reclaimed denim and cellulose, which won the Green Award at Édition Spéciale by Luxe Pack in June. At PCD in Paris earlier this year, we focused on our offer of inserts as an alternative to vac forms.

Is your board 100% recycled?

Our gray board and Eska White is 100% recycled, while Eska Black and Eska Colors are mainly made up of recycled fiber, but the liners—a small percentage of the mix—are composed of virgin fiber.

How is Eska Jeans a response to brands’ sustainability concerns?

In the fashion industry, waste and recyclability is a major issue and Eska Jeans offers the sector something new: a truly circular product. Brands are approaching us for this sustainable model and also because new European regulations will soon outlaw the destruction of unsold products, so some companies are looking for solutions to transform these goods, and why not transform them into packaging? From a marketing perspective Eska Jeans is a nice concept as the product is literally becoming part of the packaging.

What is Eska Jeans’ recycled content?

The paper is made of 50% FSC certified virgin cellulose and 50% reclaimed denim. For the inside layer, it’s a work in progress: the version we premiered at Édition Spéciale by Luxe Pack contained 14% denim fiber and the rest recycled fiber. At Luxe Pack Monaco later this month we’ll launch a version that will have a higher denim content.

From a color perspective, the material initially takes on the color of the denim fibers, but we can add sustainable inks to maintain color consistency. We can also alter the shade depending on what the brand requires, but the initial idea is to keep the color of the original fiber.

What are the technical challenges?

The main difficulty is attaining a truly rigid board, which is a signature feature across our entire portfolio; our mantra is “lay flat, stay flat” as for the games and book market it’s essential to have a maximum stability of the sheet. With this new fiber we want to reach that same performance, but as we are using denim fibers, it’s a challenge. The paper of course isn’t an issue as it doesn’t need to be rigid.

Regarding production, we are able to manufacture using our existing lines, but they need to be tweaked a bit.

What else is in the innovation pipeline?

We’ll continue our research with Eska Jeans to see if there are other textile alternatives that could work and explore the color palette. We are open to discussing new avenues of innovation with brands that have specific materials that they’d like to be able to transform.

We are open to discussing new avenues of innovation with brands

Your product offer is based on recycling. Where do you source your raw materials?

Our credo is to buy as locally as possible, so we have long-term contracts with municipalities mainly in Holland but also in Germany, a market that is known for its excellent fiber quality. The benefit of this approach is that we are ensuring consistent quality. When you are dealing in recycled materials, the fiber’s initial quality is paramount.

Our recycling process is also beneficial to our overall carbon footprint as we use the plastic that is removed from the paper before it is transformed to power our production facilities. This helps reduce the amount of natural gas that we need to purchase by more than 20%, while significantly reducing the amount of plastic that goes to landfill. Our annual production capacity today amounts to about 280,000 tons of board.

What are your areas of focus for the luxury business?

Eska’s offer is ideal for items that are a bit heavier; our rigid board is a good fit for wine and spirits, for example and as regards coffrets for fragrance and cosmetics, our board works extremely well when it comes to ‘foldability’. But we also mustn’t underestimate the potential of the jewelry and fashion segments, which (especially fashion), is increasingly concerned with sustainability. High-end consumer electronics packaging is becoming more relevant and fine foods is a focus, mainly in Italy and France. So we aren’t sticking to a single segment, and of course this business differs from one geographical market to the next.

How much does luxury account for at Eska?

Let’s say that luxury is a growing part of the business. The fact that we are investing heavily in this segment shows that we believe in its potential. Major brands have recognized that and we’ve had several successful projects in Europe and the US. This is exactly what we’re looking for, in keeping with our tagline: “architects of identity materials”!

Luxury is a growing part of the business.

By ,

18th September 2019